Technology & processes at our facilities

con-pearl North America Inc.

con-pearl North America Inc.Facts and Figures

about Con-Pearl North America Inc. & con-pearl GmbH

over

32000m²

we employ

275

at

4

our products:

∞

solutions

co-working with

9

every year we produce

10000tons of

more than

30years

everything from

1

We are there for you with

100%

over

32000m²

we employ

275

at

4

our products:

∞

solutions

co-working with

9

every year we produce

10000tons of

more than

30years

everything from

1

We are there for you with

100%

con-pearl GmbH

1strong

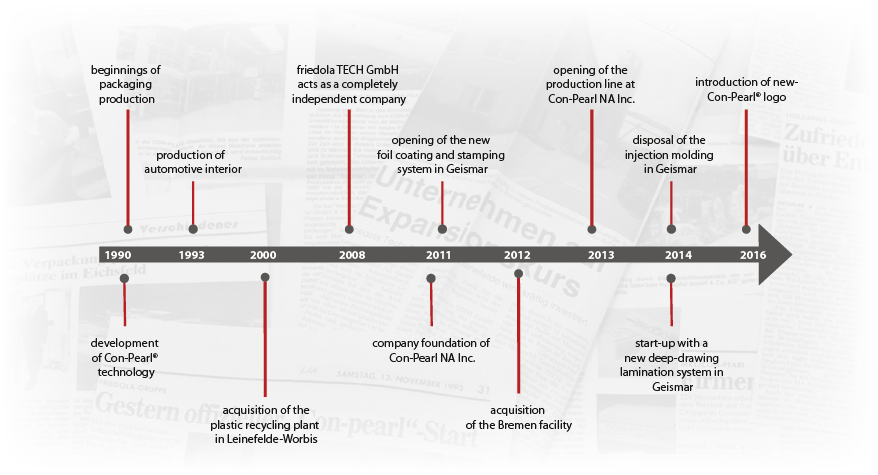

History

Technology

The parent plant in Geismar represents the entire value creation chain of our products

- foil production in extrusion and co-extrusion systems in a lab scale of up to 2450 mm wide

- plate production on deep-drawing lamination systems

- surface coating and surface finishing on stamping systems and bi-laminate extruders

- processing and fabrication of our plates as prefabricated parts using cutting, molding and joining processes in individual systems and highly-automated production lines

The Leinefelde plant is the backbone of our material treatment and material supply systems

- recyclable materials treatment in crushing and pelleting systems

- compounding and granulate production in double-worm extruders

- strict controls of our raw materials and finished granulates in our materials lab.

We produce the products for our North American customers directly in our plant in Greenville, South Carolina.

- production of packaging rings on the integrated production line using molding, stamping and joining systems

- fabrication of plates as per customer requirements using cutting and joining systems

- application consultation and prototype production on site

The plant in Bremen produces interior molded parts from textile laminates for automobile interiors

- precise, contoured form with deep-drawing systems and rear foam

- fabrication and finished products with water jet cutting, high-frequency welding systems and equipping stations

Quality management

Quality in a nutshell

…we achieve this via active, cross-department cooperation, from development to logistics. Our employees treat each other respectfully and are highly motivated to implement our high quality requirements.

Another factor for our high product quality is the cooperative work with all of our business partners. Together with our suppliers, we continue to further optimize our products. Our customers’ future expectations of our products and innovations are our focus.

By successfully obtaining certification for our integrated management system in accordance with international standards, we ensure that our processes are actively monitored and that constant improvement is not just an empty promise.

Environmental policy

Environmental policy

Economic action based on ecological principles is the objective set in the framework of our environmental policy.

1. Applicable environmental laws are complied with

The fulfillment of environmentally relevant statutory regulations is important for us on a daily basis.

2. We utilize the resources necessary for our processes responsibly and sparingly, the output of undesired products is minimized.

The use of resources is planned and materials are selected under strict consideration of the best-possible emissions levels for the environment. The output of undesired products is minimized by means of targeted measures.

3. Environmental aspects are taken into account during product development.

The products are evaluated based on environmental criteria from the development, during production and in use through to disposal.

4. Negative impacts on the environment are avoided by scheduled and controlled processes.

This is done by:

- planning an evaluating the environmental criteria of individual and overall processes. Monitoring all environmentally relevant processes and data

- efficient corrections in case of potential deviations

- preventative measures in the event of faults or accidents

In the framework of economic feasibility, the best-possible technologies are used to produce and process our products.

5. We maintain a constant dialog with suppliers, customers, employees and authorities.

This also includes:

- raising all of our employees and our customers awareness of environmental matters

- an open and factual cooperation with the authorities

- constant training and continuing education of employees

- a company-wide cooperation with regards to ecological aspects

6. The environmental compatibility throughout the company is constantly being optimized by the continuous improvement of all influencing factors.

This pertains to:

- the selection and use of technical processes

- organizational processes

- raw materials used and material selection

Energy policy

Energy policy

The company’s energy policy is communicated throughout the company.

Energy efficiency and sensibly saving energy are important economic levers for being able to compete long-term on a global market and a solid initiative in the framework of our overall responsibility. We therefore advocate the principles of the energy policy:

1. All energy-related laws and directives shall be complied with

Compliance with all applicable energy-related statutory provisions is important to us on a daily basis.

2. Energy resources shall be used responsibly and sparingly

To this end, all energy-consuming processes will be analyzed and evaluated to assess the efficiency of the use of energy and determine options for improvements and savings measures.

3. The information regarding energy consumption shall be secured and the resources for achieving our energy objects shall be made available

Operative and strategic energy objectives are pursued on the basis of continuously recorded data. Our strategic objectives are:

- Increasing energy efficiency by optimizing the process technology

- Conservative use of all energy sources

- Reducing energy consumption by implementing technical innovations

4. By implementing well-thought-out and well-planned savings measures, we continuously improve our energy-related performance

This is achieved by:

- Planning and implementing concrete energy saving projects

- Improving the efficiency of our energy consumers

- Optimizing production processes with regards to energy consumption

- Monitoring resulting impacts

5. We involve our suppliers in our efforts to improve energy efficiency

As part of the scheduled expansion or retrofitting of our technical systems, purchases are made with energy efficiency in mind:

- Representing the state-of-the-art, from devices to systems

- Offering the best-possible use of the energy resources used

6. Resource conservation and energy conservation is a matter for all of our employees

With comprehensive information regarding special measures in our company, we motivate our employees to think and act in an environmentally-friendly manner at work.

- Home

- Company